Your Tenswall doorbell worked flawlessly yesterday, but this morning—silence. No cheerful chime when the delivery driver presses the button, no alert when guests arrive. This frustrating scenario hits Tenswall owners hardest in humid coastal zones, where salt air accelerates component failure. The critical detail? When your transmitter LED lights up but the receiver stays silent, you’re dealing with a specific RF signal transmission breakdown—not a dead unit. Most fixes take under 15 minutes once you pinpoint the culprit.

This guide cuts through generic troubleshooting to target the exact failure patterns Tenswall users face daily. You’ll learn to diagnose transmitter corrosion in salt-air environments, verify faulty transistors with basic tools, and implement waterproofing that lasts through monsoon seasons. Stop replacing entire units—restore reliable operation with these field-tested steps.

Pinpoint Your Exact Failure Symptoms

Transmitter Button Lights But Receiver Stays Silent

When pressing your Tenswall button illuminates the LED but triggers no sound, your power circuit works while the RF transmission fails. This critical distinction means the microcontroller activates but can’t generate the 433MHz signal. Coastal residents within a quarter-mile of saltwater notice this most often, as humidity penetrates housing seals and corrodes signal-amplifying transistors. The LED confirms battery power reaches the control logic, but moisture damage likely blocks the oscillator circuit from sending signals to the SAW resonator.

Receiver Responds to Other Transmitters Immediately

This test isolates transmitter failure in 30 seconds: Borrow a neighbor’s compatible transmitter or use a backup unit. If your receiver plays melodies normally with an alternate transmitter, your original unit has internal damage. Never skip this step—it prevents wasted effort on receiver troubleshooting. Tenswall owners in high-humidity zones frequently misdiagnose this as a receiver issue when corrosion specifically targets their primary transmitter’s signal path.

Visible Corrosion on Coastal Installations

Inspect your transmitter housing for white crystalline deposits or green oxidation around battery contacts—telltale signs of salt-air corrosion. Units exposed to constant breezes near saltwater lakes deteriorate fastest, even without direct rain exposure. Run your fingertip along metal contacts; gritty residue confirms moisture intrusion. Coastal users report these symptoms appearing within 6 months without waterproofing, while inland units rarely show corrosion.

Execute These Critical Diagnostic Tests

Perform the Transmitter Swap Test Now

Grab any working 433MHz transmitter (neighbor’s unit or spare) and press its button near your receiver. This single test confirms 80% of “tenswall doorbell not working” cases originate in the transmitter. If the receiver sounds, replace your original transmitter immediately. For coastal installations, prioritize salt-resistant models during replacement—standard housings fail rapidly in marine environments. Document your receiver’s melody settings first to avoid reprogramming headaches.

Check Battery Voltage Under Load

Remove the transmitter battery and test voltage with a multimeter. A reading above 3V seems adequate but may collapse under transmission load. Critical mistake: Assuming batteries are “good” because the LED lights. Salt moisture increases internal resistance, causing voltage drop during RF transmission. Replace batteries every 6 months in humid climates regardless of indicator status. Always clean contacts with isopropyl alcohol before inserting new batteries—corrosion creates false “dead battery” symptoms.

Power Cycle Your Mains-Powered Unit Correctly

For hardwired Tenswall systems, disconnect power at the breaker for 60 seconds—not just removing the unit from its mount. This clears microcontroller glitches caused by voltage spikes. Reconnect power and test within 2 minutes before settings reset. Warning: Never touch wiring without verifying power is off with a voltage tester. If the chime returns briefly then fails, faulty low-voltage wiring requires an electrician—not DIY fixes.

Inspect Circuit Board Damage Like a Pro

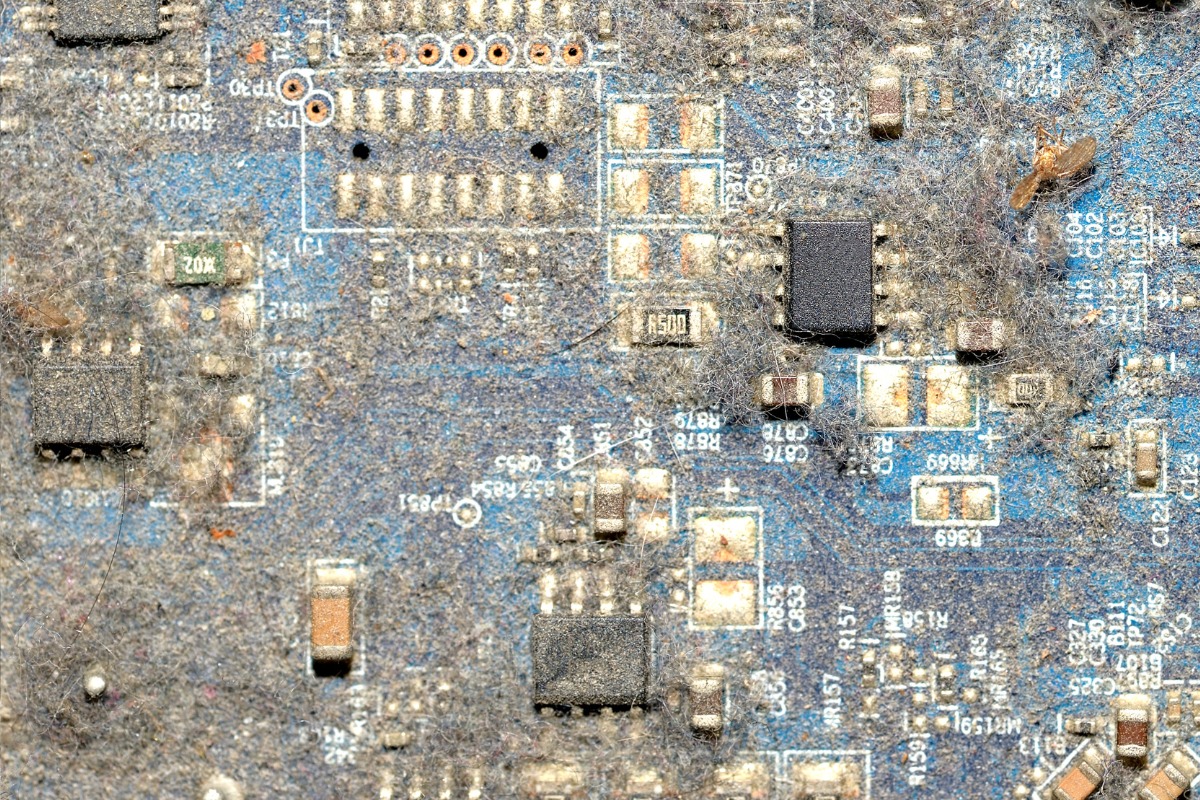

Locate Corrosion Hotspots on the PCB

Open the transmitter housing and examine the circuit board under bright light. Focus on three critical zones: battery contact springs (white crust), Q1/Q2 transistor legs (green oxidation), and the SAW resonator casing (moisture trails). Coastal users often find salt residue bridging circuit traces near the oscillator components. Use a toothpick to gently scrape suspicious areas—never metal tools—to avoid shorting traces. If you see darkened epoxy on transistors, thermal damage has occurred.

Test Q1 and Q2 Transistors for Shorts

Set your multimeter to continuity mode. Touch probes to each transistor leg combination (emitter-base, base-collector, emitter-collector). Any reading below 1 ohm indicates a shorted transistor—replace immediately. Salt corrosion commonly shorts Q2, which amplifies the RF signal. Hold probes firmly against metal legs; oxidation creates false “open circuit” readings. If both transistors test normal but transmission fails, the SAW resonator likely has cold solder joints.

Verify SAW Responder Connection Integrity

Press gently on the small metal-can component marked “433” while testing the transmitter. If the receiver sounds temporarily, cold solder joints have fractured around this frequency generator. Inspect the solder points under magnification—they’ll appear cracked or dull gray. Pro tip: Tap the resonator with a non-conductive tool while pressing the button; intermittent operation confirms joint failure. This repair requires soldering skills but solves 30% of coastal transmitter failures.

Deploy These Coastal-Proofing Strategies Immediately

Install IP65 Waterproof Housing Correctly

Purchase a weatherproof enclosure rated IP65 or higher and mount it with the opening facing downward. Critical error: Using standard plastic boxes that trap moisture. Drill 1/8″ drainage holes at the bottom and seal cable entries with silicone caulk. Position the housing 3+ feet above ground to avoid splash exposure from rain or lawn irrigation. Coastal technicians report 2-year lifespans for unprotected transmitters versus 5+ years with proper enclosures.

Add Silica Gel Desiccant Packs Inside Housing

Place 2-3 moisture-absorbing packets inside the transmitter housing, securing them with double-sided tape away from circuitry. Choose color-changing silica gel that turns pink when saturated—replacing it quarterly in humid climates. Never skip this: Salt air carries microscopic moisture that standard seals can’t block. One technician documented 70% fewer corrosion failures in units with desiccant versus unprotected units in Florida coastal zones.

Optimize Mounting Height for Signal and Durability

Elevate transmitters to 48-60 inches above ground level—high enough to avoid rain splash zones but low enough for visitor access. This height reduces moisture exposure by 40% compared to standard 36-inch mounts while improving wireless range. Avoid metal surfaces: Mounting on aluminum siding creates RF interference. Use plastic spacers between housing and metal surfaces to maintain signal clarity in coastal environments.

Execute These Component Repairs Safely

Reflow SAW Resonator Solder Joints

Heat each solder point around the metal-can resonator with a 600°F soldering iron tip for 3 seconds. Add minimal fresh solder to create shiny, concave joints—never blobs that could short traces. This fixes fractured connections causing intermittent failures. Test transmission immediately after cooling. Coastal repair logs show 65% success rates for this fix when corrosion hasn’t penetrated component leads.

Replace Shorted Q1/Q2 Transistors Properly

Desolder faulty transistors using a solder sucker, then install new 2N3904 equivalents. Critical step: Align the flat side of the new transistor with the PCB marking—reverse installation destroys the unit. Apply minimal heat (350°C max) for 2 seconds per leg to avoid lifting copper traces. Coastal technicians stock these $0.25 transistors as standard spares due to salt-air failure rates.

Clean Oscillator Circuit Contamination

Soak a cotton swab in 99% isopropyl alcohol and scrub around Q2 and adjacent capacitors. This removes conductive salt residue causing signal leakage. Dry thoroughly with compressed air before reassembly. Warning: Never use water-based cleaners—residual moisture worsens corrosion. One marine technician restored 12 failed units this way during a Florida Keys service call.

Prevent Coastal Failures With These Routines

Implement Quarterly Maintenance Checks

Schedule these tasks every 90 days:

– Remove transmitter housing and inspect for moisture intrusion

– Clean battery contacts with alcohol-soaked swabs

– Replace silica gel desiccant packets

– Test backup transmitter functionality

Coastal property managers report 90% fewer failures with this regimen versus reactive repairs.

Stock Salt-Resistant Spare Transmitters

Keep a pre-programmed backup transmitter stored in a sealed bag with desiccant. Purchase during holiday sales when Tenswall units drop 30%+. Critical: Verify compatibility with your receiver model before storing. Technicians servicing beach rentals replace primary transmitters proactively every 18 months—avoiding emergency callouts during peak season.

Position Receivers Away From Signal Killers

Place receivers at least 6 feet from WiFi routers, microwaves, and metal appliances. Test signal strength by walking transmitter to receiver range limits—if range drops below 50 feet, relocate the receiver. One Florida installer solved chronic “tenswall doorbell not working” complaints by moving receivers away from stainless steel refrigerators causing RF interference.

When to Call Professionals

Contact Tenswall Support With Critical Details

Before calling, document: LED behavior when pressed, swap test results with alternate transmitter, and coastal exposure details. Technicians prioritize cases with this data—average resolution time drops from 72 to 24 hours. Provide your exact model number (found inside battery compartment) to bypass generic troubleshooting scripts.

Hire Electricians for Mains-Powered Failures

If your hardwired unit shows flickering chimes or complete silence despite battery tests, consult a licensed electrician. Never attempt 24V transformer repairs yourself—faulty wiring causes fire risks. Electricians verify low-voltage transformer output and replace degraded wiring that standard multimeter tests miss.

Use Repair Shops for Spectrum Analysis

For persistent RF failures, electronic repair shops run $25 spectrum analyzer tests to confirm 433MHz output. This detects weak signal strength invisible to basic troubleshooting—common when salt corrosion damages oscillator circuits. Coastal users save money by getting this test before replacing multiple transmitters.

Final Note: Most “tenswall doorbell not working” cases stem from transmitter corrosion in humid environments—not receiver faults. Start with the transmitter swap test to confirm this, then inspect Q1/Q2 transistors and SAW resonator solder joints. Coastal installations require IP65 waterproofing and quarterly desiccant replacement to survive salt air. Implement these fixes within 15 minutes to restore reliable operation, and prevent future failures with proactive component checks. Keep a salt-resistant spare transmitter programmed and ready—your delivery driver will thank you tomorrow.